Homepage Banner Slideshow

Homepage Banner Slideshow

icon menu bar

icon menu bar

Custom Manufacturing Text

Custom Manufacturing Text

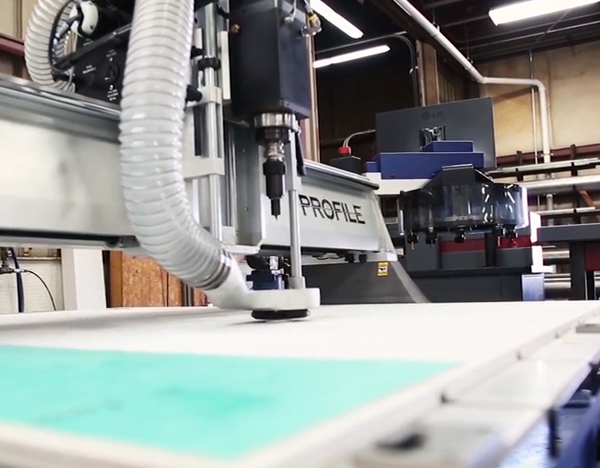

Custom Manufacturing

Allegheny York is committed to high quality and timely service. By employing talented personnel, investing in new machinery, and enhancing our capabilities through upgrades, we are able to offer a vast range of tooling for standard Hydraulic and Pneumatic Seals as well as Custom Molded Shapes. Our manufacturing capabilities include CNC Machining, Compression and Injection Molding which gives us the ability to custom mold virtually any shape or design. For all of your engineered shapes, manufactured to print or sample, we have the technology to supply you with product that exceeds your expectations.

S2K Commerce - Shopping Cart

S2K Commerce - Shopping Cart

Back to Top Button

Back to Top Button

Custom Parts Block

Custom Parts Block

Allegheny York Custom Solutions

Allegheny York is a custom manufacturer serving customers in a variety of industries worldwide since 1972. We provide custom plastic injection molding, CNC machining of plastic and metal, and compression molding. We offer low cost, fast turnaround, and quotes.

Injection Molding

Many different plastic and elastomer type products are produced in our Injection Molding Department. Sizes available up to 12".

Quick Turnaround

Low Cost

High Quality

Compression Molding

It takes expertise to produce quality products using a compression mold. Our 35+ years of experience with rubber compression molding helps to benefit every client. We can help guide you through the process of using compression molded rubber to create any products you need.

CNC Machining

If you have prototypes and short runs, CNC machining may be the best solution. Allegheny York can help you manufacture products which are difficult or nearly impossible to make on conventional machinery.

Plastic or Metal

Prototype & Low-Volume Parts

Variety of Materials Available

Engineering Services

Our skilled team of engineers is always available to answer your questions and will identify your part or help start the process for fabricating a new part. This hands-on approach sets us apart and helps our customers rest assured they will get the best parts and service available.

We utilize SprintMVP® automatic measurement systems to accurately measure fine features that require multi-step measurement routines,automatically combining autofocus, edge detection, programmable lighting, laser scanning and touch probing.

Our engineers are fluent in the use of industry standard software, Solidworks®, which helps our customers save time, reduce costs, increase accuracy, improve quality, facilitate collaboration and ensure design for manufacturability throughout the design process.

Our quality control standards require our team to manually review and inspect every custom made part. In ongoing consultation with our customers, we will revise schematics and tooling as needed.

Injection Molding Capabilities

2014 SUMITOMO SE130EV

Tonnage:

130 Metric Tons

143 US Tons

Shot Size:

8.6 OZ

2015 SUMITOMO SE100EV

Tonnage:

100 Metric Tons

110 US Tons

Shot Size:

6.8 OZ

2015 SUMITOMO SE75EV

Tonnage:

75 Metric Tons

82 US Tons

Shot Size:

1.7 OZ

2014 SUMITOMO SE50EV

Tonnage:

50 Metric Tons

55 US Tons

Shot Size:

1.3 OZ

1988 NISSEI

Tonnage:

360 Metric Tons

396 US Tons

Shot Size:

40.24 OZ

MATSUI HOPPER

Material Drying System

Compression Molding Capabilities

2013 PAN STONE

(4 Machines)

Platten Size:

16" x 18"

Tonnage:

100 Metric Tons

110 US Tons

2013 PAN STONE

(4 Machines / Vacuum)

Platten Size:

16" x 18"

Tonnage:

Vacuum 100 Metric Tons

110 US Tons

2015 PAN STONE

Platten Size:

42" x 42"

Tonnage:

600 Metric Tons

661 US Tons

CNC Machining Capabilities

2023 DMH 850H

Type:

CNC Turret Lathe

with 8 Tool Capacity

Material:

Rubber and Plastic

2016 DMH 400

Type:

CNC Turret Lathe

with 12 Live Tool Capacity

and Bar Feeder

Material:

Rubber and Plastic

2016 MORI SEIKI

DURO TURN 2050

Type:

CNC Turret Lathe

with 12 Live Tool Capacity

Material:

Plastic and Steel

Other Capabilities

MACHINE SHOP

The first step in meeting customer's satisfaction is in the preparing of the mold cavities to meet the required specifications.

We currently have over 5,000 molds and dies of vee packing and custom parts.If a mold or die is not already in our extensive inventory, then we can design and machine the tool to meet almost any specification.

TRIMMING AND ROUTER CUTTING

PAN STONE® V-13 KNIVES TRIMMER for the highest quality hard rubber and plastic components.

HUDSON® CLICKER DIETRIMMERS produce clean and uniform rubber parts and gaskets for large and small production runs.

CNC ROUTER CUTTING uses a thin gauge router and can be

computer programmed to cut multiple shaped parts out of a single sheet as large as 4’x 8’, eliminating the need for additional setups, maximizing yields of parts per sheet and resulting in cleaner finished edges. Faster and less labor intensive, results in increased cost efficiency and higher quality parts.

Custom Seal Text Insert

Custom Seal Text Insert

These manufacturers use a production line to create tons of identical parts on automated machines that run 24/7 with very little human interaction. Many overseas manufacturing plants operate this way. Automation is the primary means to produce parts.

Pros of Mass Production

Mass production is more cost efficient for companies producing large quantities of metal and plastic parts. Because machines do most of the work, labor costs are relatively low. Identical parts are easier to come by because everything is programmed and research-driven.

If maintaining an inventory of spare parts is important, mass production can easily provide more than necessary.

Cons of Mass Production

Human interaction on the production line is limited. If quality is an issue, there is less oversight to catch issues that appear during the process. Minimum run quantities tend to be extremely high, so waste is another issue. If a part needs design changes, it is more costly to pull something out of production to work out issues.

Custom Manufacturing

Creating a small number of parts, or an untested part that may require design changes are both situations that work well for custom manufacturing. Because of the amount of human involvement over the course of production, quality is easier to monitor and stopping production is not as much of an issue.

Pros of Custom Manufacturing

Custom manufacturing has lower minimum quantities, if any at all. Though lower volumes will be more expensive, these parts are easier to make changes to during production.

Quality inspections are more frequent, and many times involve more than just observing the appearance for flaws. Adjustments can be made to account for quality problems that didn’t appear until production began without as much difficulty as mass production.

Cons of Custom Manufacturing

Because of the higher degree of human interaction with custom manufactured parts, the downside is a part that costs more to produce.

Less automation also means more chances for errors, but even small runs usually involve CNC machines that are programmed to create identical parts, so this isn’t a huge issue.

Conclusion

While mass production has some advantages, unless you’re producing parts by the millions there really isn’t much of a reason to go that route.

Custom manufacturing provides a durable part, with the option to make changes as necessary. This eliminates waste and allows you to create only as many parts as needed for a short period of time.

Have a project in mind?

Upload your file to our contact form for a hassle-free experience today!